Searching for specialized West Palm Beach dryer vent cleaning experts? We deliver safe, code‑compliant airflow using HEPA‑contained extraction, rotary brushing, and instrumented verification. You'll experience reduced drying times, reduced fire risk, and enhanced indoor air quality in our coastal humidity. We meticulously assess run length, elbows, materials, and termination based on NFPA 211/IMC, then document pre/post CFM, static pressure, temperature rise, and photos. We fix crushed flex, reinforce joints with UL foil tape, and check damper function. See how we demonstrate measurable improvements next.

Critical Summary

- Licensed dryer vent technicians operating in West Palm Beach, improving safety from fires, air quality indoors, and power efficiency per NFPA 211 and manufacturing guidelines.

- Full-service cleaning: offering rotary brushing, termination hood cleaning, HEPA negative-pressure capture, and UL-2158A standard repairs and sealing.

- Thorough diagnostic evaluation with static pressure readings, airflow analysis, temperature rise verification, and motor amp readings; accompanied by before and after documentation and complete diagnostic findings.

- Rapid attention needed for warning signs: extended drying cycles, hot cabinets, strange odors, weak exterior ventilation, or tripped thermal safety switches.

- Seaside-specific solutions that address humidity, condensation, and corrosion challenges; offering comprehensive care solutions for residential properties, condominiums/HOAs, and commercial buildings.

Why Dryer Vent Cleaning is Essential in West Palm Beach

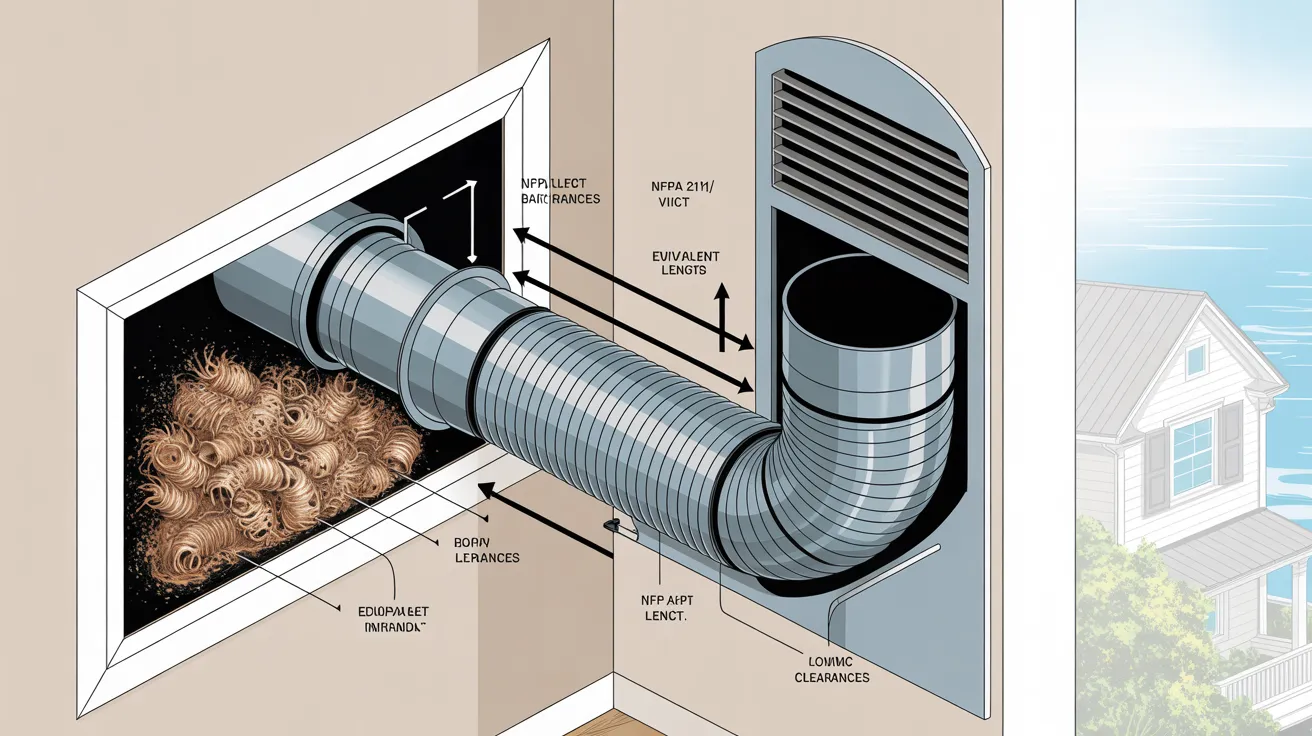

Given that lint collection is a leading cause of residential fires, periodic dryer vent cleaning in West Palm Beach is a critical safety measure that reduces fire danger, enhances airflow, and keeps equipment compliance with manufacturer and NFPA 211/CSA C22.1 guidance. You'll also shield wiring, terminations, and junction ducts from thermal strain and backpressure. By clearing obstructions, you reestablish design static pressure, maximize exhaust movement, and decrease cycle times, boosting energy efficiency and prolonging motor life.

In regions with coastal and high-humidity climates, maintaining appropriate humidity levels in your laundry area is crucial. Properly cleaned vents eliminate moisture effectively, minimizing mold formation, condensation issues, and ductwork deterioration. Professional maintenance confirms appropriate duct system standards, including properly constructed metal walls, properly sealed joints, and adequate vent termination spacing, while checking proper utility connections and damper operation. This ensures reliable performance that meets safety codes all year long.

Critical Signs Your Dryer Vent Needs Urgent Attention

When your dryer displays thermal stress, ventilation problems, or utility abnormalities, consider these red flags that need immediate attention. If the unit's cabinet or door feels unusually hot, the exhaust duct could be obstructed. Extended drying cycles point to reduced airflow and pressure issues throughout the vent run. The presence of musty odors typically indicates moisture buildup from poor exhaust flow. Lint accumulation around the outdoor hood, non-functioning vent flapper, or damaged flexible ducting all indicate restricted airflow.

Be alert to diminished exhaust stream at the endpoint, a blown thermal fuse, or continuous switching on the high‑limit thermostat. Heat discoloration, shaking ducts, or rattling elbows point to inadequate support or fasteners. Should you detect the gas burner short‑cycling or detect erratic amperage, immediately shut down the unit and schedule a vent checkup.

Key Benefits: Fire Safety and Air Quality Standards

While a dryer may seem like a routine appliance, its venting system poses a significant fire hazard should lint collect or ventilation become compromised. You can reduce fire risks by maintaining proper duct dimensions, using metal connections, and following code-approved termination. Adequate ventilation decreases temperature, improves smoke safety, and minimizes flammable lint deposits. Moreover, you shield inhabitants from CO gas intrusion when gas dryers have unrestricted airflow and connections stay sealed.

Well-maintained ducts boost indoor air quality. Efficient air filtration through the system and unobstructed exhaust facilitate allergen elimination by removing debris, allergens, and particles as opposed to recirculating them. Managed exhaust improves humidity regulation, reducing dampness problems and wall cavity condensation. Briefer cycles result in lower thermal stress, increasing fabric longevity. Complying with NFPA 211/54 clearances and UL-listed components protects reliability and wellbeing.

Our Professional Dryer Vent Cleaning Procedure

We begin with a detailed code-compliant inspection and assessment to identify duct damage, blockages, and terminal problems. We proceed with thorough removal of lint and debris using proper agitation and negative-pressure collection to avoid spreading. In conclusion, we validate results with calibrated airflow testing and document that exhaust performance satisfies both manufacturer guidelines and local regulations.

Assessment and Inspection

Before commencing any maintenance, our technicians perform a detailed inspection and code-based evaluation to determine baseline conditions and detect potential hazards. We begin with a visual examination of the coupling hose, vent pathway, termination cover, and spacing to ensure UL-listed components, correct routing, and secure connections. We validate duct composition, length, and equivalent elbows against manufacturer specifications and Florida Building Code requirements.

We measure airflow levels, static pressure readings, and backdraft damper performance to identify potential restrictions or improper venting. We conduct moisture analysis at the lint trap, connection points, and exterior cap to identify moisture problems or crushed ducts. We examine proper ventilation, exhaust separation, and electrical connections. You'll receive detailed findings, safety priorities, and code-compliant solutions before proceeding with service.

Debris and Lint Removal

Once we've recorded initial conditions, we proceed straight into cleaning out lint and debris using methods specifically matched to your vent system's requirements. We begin by disconnect the power supply, protect the appliance, and install professional HEPA filtration to establish negative pressure. You'll observe us utilize rotary brush rods or air-whip agitation calibrated to the duct diameter, thoroughly clearing compacted dryer lint and vent debris without stressing joints or flexible components.

We proceed from termination to the unit, carefully cleaning connectors, seams, and elbows, then vacuuming with antistatic equipment to prevent debris re-entrainment. We carefully bag and document the extracted debris for your records. We thoroughly clean the termination hood, damper, and bird screen, maintaining smooth functionality. Lastly, we check and re-seat the clamps, check all set screws, and replace any noncompliant foil or plastic junctions with UL-2158A listed parts.

Verifying Airflow Testing

Confirm functionality through instrumented airflow measurement. Once debris is cleared, you should confirm system efficiency using calibrated measurement tools including hygrometers, anemometers, and manometers. Record baseline metrics at the exterior termination with the dryer operating and connected on a timed cycle. Measure and document duct static pressure, velocity, and volumetric flow. Evaluate the readings against factory guidelines and ACCA/ASHRAE standards to ensure safe function.

Conduct pressure mapping along critical areas including connector hose, appliance collar, exterior hood, and inline fittings. Detect abnormal pressure drops that indicate residual restriction, damaged flex, or faulty backdraft damper. Confirm that air movement successfully eliminates lint without exceeding prescribed standards for flex duct.

Log environmental conditions, including humidity and temperature to provide context for performance results. Should targets fall short, provide appropriate corrective measures. Finish up by incorporating performance results to service records for compliance purposes and future reference.

Sophisticated Tools and Approaches We Utilize

Although every home is different, we employ a systematic set of tools to thoroughly clean vents and meet code. You get a detailed approach that prioritizes fire safety and optimal air circulation. We start with mechanical assessment to chart the complete duct network, verify elbows, and identify constrictions without removing finishes. Next, we use thermal imaging to detect hidden heat variations indicating lint accumulation, crushed flex, or loose joints.

We use rotating brush mechanisms matched to duct diameter, then collect contaminants with HEPA-filtered negative pressure to prevent indoor re-entrainment. When regulations allow, we use flexible whip heads for sensitive portions and synthetic poles for solid metal sections. We track motor amperage, verify backdraft damper functionality, and secure joints using UL-listed foil tape, rather than standard duct tape, ensuring durable, code-compliant solutions.

Professional Services for Residential and Commercial Properties

We deliver customized residential solutions that accommodate equipment specifications and duct parameters while following NFPA 211 and manufacturer standards. For condos, we coordinate entry coordination, record outcomes, and adhere to HOA bylaws and local fire code to ensure shared shafts and booster fans compliant. Businesses benefit from industry-standard maintenance services with regular cleaning, airflow monitoring, and detailed reports to satisfy OSHA requirements and AHJ assessments.

Personalized Home Solutions

Engineered exclusively for different living spaces, our specialized residential dryer vent services tackle the particular code requirements, airflow considerations, and access challenges found in various residential properties including houses, condominiums, and townhouses. We begin with an extensive inspection aligned with NFPA 211 and IRC standards, analyzing duct length, elbow count, termination type, and material. Following this, we remove lint and blockages using specialized rotary brushing and HEPA-contained negative pressure to reestablish design CFM and static pressure targets.

We enhance energy efficiency by checking vent run geometry, correcting crushed flex, sealing joints with UL-listed foil tape, and setting proper backdraft damper tension. We provide documentation: detailed reports showing before/after airflow, amperage, temperature differences, and photographic evidence. Given West Palm Beach humidity, we suggest seasonal scheduling before peak dryer use, ensuring efficient performance, quicker drying cycles, and extended equipment life.

Condo Association Compliance

Due to the risk concentration in multi-unit properties, our condo association compliance program synchronizes dryer vent services with NFPA 211, NFPA 70 (NEC), and the International Residential/Mechanical Codes, plus your governing documents and coverage mandates. We standardize workflow, access guidelines, and reporting to satisfy association requirements while minimizing resident impact.

We commence with safety evaluations of ventilation shafts and internal duct systems, assessing material type, run length, termination, backdraft dampers, and makeup air. You'll receive safety-prioritized documentation, visual documentation, and remediation strategies. Our experts remove blockages, replace non-compliant flexible materials, seal joints with UL‑listed materials, and set service intervals based on occupancy and lint load.

All reports are timestamped and recorded, keep comprehensive unit activity logs, and deliver comprehensive service verification for insurers, boards, and fire inspectors.

Commercial-Grade Maintenance Programs

As fire danger grows with lint accumulation and usage time, our professional maintenance solutions establish dryer vent care for houses, apartments, and commercial spaces under the same standards-based framework. You'll benefit from NFPA 211/54-aligned assessments, air circulation analysis, and documented cleaning intervals aligned with facility use and occupancy levels.

We implement service contracts that specify scope, frequency, and response SLAs, protecting you from unexpected outages and violations. Our dedicated technicians examine proper duct materials, connections, and damper performance, then evaluate static pressure and velocity to validate system efficiency. We eliminate impediments, reseal joints, adjust building stacks, and replace flexible ducts with metal ones when necessary.

You'll get timestamped reports, initial and final readings, and remediation documentation-crucial evidence for insurance claims, AHJ inspections, and administrative assessments.

Recommended Frequency for Dryer Vent Maintenance

Experts recommend to arrange professional dryer vent cleaning annually, or more often if you have heavy usage (multiple loads daily), your vent configuration is complicated, or you spot concerning indicators like extended drying times, buildup of lint, or burning odors. In West Palm Beach's humid climate, lint will become damp, adhere to duct walls, and restrict air movement more quickly, so make sure to maintain annual service intervals. Plan maintenance according to use: quarterly for commercial facilities or big households; semiannual for typical homes; annual for light usage.

Set up routine inspection alerts at the start of hurricane and winter dryer seasons to evaluate ventilation efficiency, termination flapper functionality, and transition duct integrity. Remember to confirm external ventilation gaps, vent guard integrity, and ensure that ventilation conforms to manufacturer CFM specifications and regional regulations.

Transparent Pricing and What's Included

After setting your service interval, you'll know the complete cost breakdown. We provide clear cost projections prior to starting, with scope defined by vent length, termination points, and code-access constraints. We specify mechanical agitation, more info HEPA-contained extraction, ventilation assessment, flow rate testing (pre/post CFM), and termination cap cleaning. If needed, we note bird-guard replacement and approved connector modifications.

Choose flat rate pricing for basic single-run setups, or opt for service bundles that include lint alarm installation, cleaning, and airflow balancing. We maintain detailed records with photos, static pressure readings, and NFPA 211/IMC compliance notes. Our detailed invoices list labor, materials, access fees, and any roof-safety surcharge. Zero hidden charges - any extra services (rerouting, repairs, or remediation) demands your written authorization before beginning.

Real Customer Stories and Local Testimonials

Since outcomes matter more than guarantees, our customers showcase concrete results: reduced dry times, confirmed airflow improvements, and static pressure restoration to code-compliant levels. In Client feedback, you'll discover quantified outcomes: 30-50% reduction in cycle times, fans restored to factory specifications, and lint accumulation decreased to safe levels. You benefit from NFPA 211-compliant techniques, UL-approved materials, and proven flow rate increases.

Local milestones feature apartment complexes in West Palm Beach successfully passing HOA safety audits after remediation of compromised flex runs and incorrect terminations. Safety inspections show a decrease in dryer-fire risks where we've corrected airflow restrictions and repaired backdraft damper function. You'll receive before/after meter readings, images, and maintenance intervals. This detailed reporting enables you to plan filtration updates, manage energy use, and maintain code compliance.

Questions and Answers

Are Your Technicians Licensed, Insured, and Background-Checked?

Indeed. Our team includes licensed technicians who comply with state and local codes, hold current certifications, and implement manufacturer specifications. Our company maintains full liability and workers' compensation insurance for your safety. We conduct thorough background checks and regular safety training, including lockout/tagout, confined space awareness, and NFPA 211/IMC compliance. We record procedures, confirm clearances, and assess airflow and termination integrity. You can expect detailed reporting, chain-of-custody for keys, and visually documented results.

Are Same-Day and Emergency Dryer Vent Services Available?

Indeed, we offer urgent dryer vent service. We give priority to life-safety hazards, clogged venting, and temperature concerns with immediate service and same-day response. We deliver a NFPA 211/IRC-compliant examination, airflow and static-pressure tests, and system cleaning to factory specifications. We check ventilation components, vent terminations, and clearances, and report observations. You'll receive a written safety report, image evidence, and maintenance advice, with service guarantee and final testing.

Do You Handle Rooftop and Difficult-To-Access Exhaust Outlets?

Yes, we maintain difficult-to-access exhaust outlets. You receive technicians qualified in rooftop access, fall protection, and confined-space procedures. We implement OSHA-compliant safety equipment and secure anchoring systems. We check termination caps, backdraft dampers, bird guards, and distances. We apply rotary brushing, HEPA vacuums, and camera inspections to guarantee full airflow. You'll get comprehensive reports, visual documentation, and flow measurements. If needed, we replace damaged caps and secure penetrations to factory specifications.

Can Cleaning Void My Dryer's Manufacturer Warranty?

Professional dryer cleaning won't invalidate your manufacturer's warranty. For instance: with regular professional maintenance, your service professional clears accumulated lint, optimizes airflow, verifies temperature levels, and provides code-compliant documentation. Maintaining these service records validates warranty claims through proof of proper care. Select licensed professionals who comply with NFPA 211 requirements and manufacturer guidelines, don't allow improper dismantling, and ensure detailed documentation with photos and receipts. Professional technicians document any existing damage prior to service to maintain warranty validity.

Can I Get Before-And-After Reports for Airflow and Lint Volume?

Yes. You receive documented airflow measurements and a detailed lint evaluation following our service. We record pre- and post-cleaning CFM measurements (CFM) using a calibrated anemometer and note static pressure changes. When examining lint, we calculate mass and quantity, detect combustible buildup, and capture images of findings. Documentation covers vent path conditions, code-compliance observations, and safety guidelines. You'll see comprehensive, verifiable improvement data to help with maintenance planning and insurance or property management documentation.

Wrapping Up

You prioritize safety, efficiency, and code compliance - and so do we. The fire risk from lint accumulation is significant; the U.S. Fire Administration documents nearly 2,900 dryer fires each year, with most starting in clogged vents. Picture a vent packed like a felt blanket limiting airflow and overheating components. Professional cleaning will minimize fire dangers, upgrade IAQ, and satisfy manufacturer and NFPA 211 requirements. Make sure to schedule regular service, document findings, and confirm airflow and termination. These steps will protect your property, lower energy consumption, and maintain your system stays within specifications.